Middlesex University ‐ Platt Halls of Residence

Platt Halls of residence are student accommodation blocks. Each one containing eight flats and each flat contains six en‐suite rooms with a communal kitchen and meeting area. They were initially constructed in 1994 using pre‐cast concrete panels with a brick facing, they have been home to thousands students over the years, and now they needed the help of fire damage cleaners.

The problem

A fire started in a small storage yard in the buildings at the rear of the accommodation blocks. It soon spread to workshops and warehousing directly behind the accommodation blocks, these buildings were old and constructed manly from wood which aided the flames to spread. Fire fighters battled to control the fire and eventually had to use the blocks as a wet wall. The fire was contained then driven into the blocks and, four and a half days after it started, it was extinguished.

The blocks sustained much fire damage, but the prompt action of the Ideal Response’s fire damage restoration played a major part in saving the main fabric of the building.

Most of the rear windows had exploded under the extreme temperature allowing the fire to take a hold of some third floor rooms. The flames caught the woodwork under the eaves and spread into the loft space, destroying all the wooden joists, causing the roof to collapse. The fire fighters pumped thousands of gallons of water into the buildings to protect them, although this water protection saturated the walls, floors and ceilings on every level.

The kitchens in each flat were constructed from chipboard which absorbed massive quantities of water, causing severe swelling, fitted wardrobes and cupboards in the student rooms suffered a similar fate rendering them beyond salvage. Fire damage restoration services in East Sussex were required as soot from the fire was washed in and contaminated the fabrics and furnishings within each of the areas.

Three blocks had been affected, each one was four storeys high and divided up into eight apartments, each containing six bedrooms and one kitchen, giving a total of 56 rooms per block with an internal volume of 2325 m³.

Traditional drying equipment would have taken many months to dry three buildings of this size and with this degree of water damage ‐ a hydronic heating system using the “pressured chamber” system was acknowledged to be the quickest, most efficient and economic method of drying the blocks.

Speak to our restoration experts now

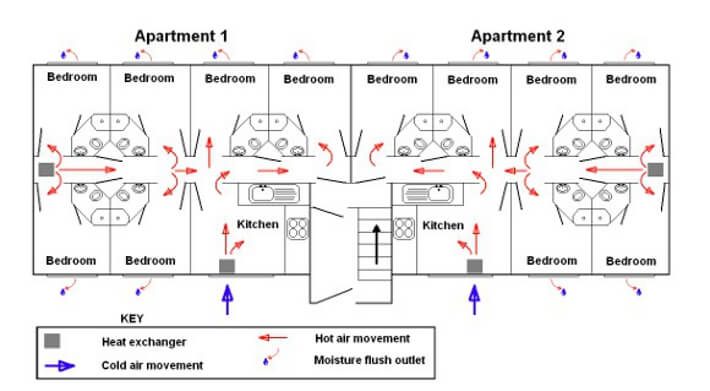

01622 926 505The floor plan of one block showing the positioning of the heat exchangers and the air movement, each apartment on all floors in each block are identical.

The solution – After Fire Cleaning Services

The “pressured chamber” system was used with two hydronic heaters; each one containing; one water heater and six heat exchangers. Two heat exchangers were positioned in each apartment (as shown on the floor plan) allowing the two machines to dry six apartments at the same time. A heat exchanger was placed in the kitchen window to create heat and positive pressure and the other, at the far end of the corridor to generate heat only. All broken windows were temporally repaired then all the windows were slightly vented to allow the positive pressure to escape.

The “Pressured Chamber” System

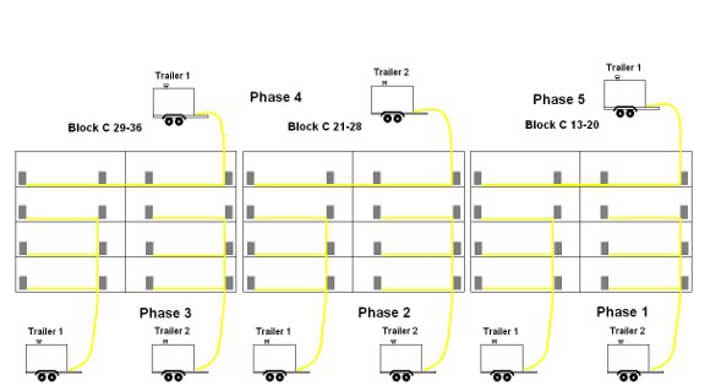

Pressured Chamber is the method of using air as a medium to extract water out of a property using heat and positive pressure. A heat exchanger is used draw air from outside, heat it and push it inside. The hot air travels around a room using the natural movement of convection; hot dry air rises up and displaces the air on the ceiling. The air on the ceiling then rolls down the walls, as the heating system reduces the airs RH to less than 5%, the air then acts as a sponge, absorbing moisture from both the surface and mass of the host materials. The positive pressure takes the “sponge like” humid air and pushes it out of the nearest air vent (air bricks, windows, etc). In this case the drying was carried out in 5 phases.

Each exchanger generates 1200 m³ of hot dry air every hour, of the two exchangers per apartment; the one sited in the kitchen window provided the positive pressure. It drives 1200 m³ of hot dry air into the apartment and insures that 1200 m³ of humid air, leaves. The other exchanger positioned at the end of the corridor re‐heats and re‐circulates the air.

Given the apartment volume as 275 m³, the air was be replenished 4.3 times every hour using this drying method, each phase was completed in just 7 days. The whole accommodation project was successfully dried in 35 days. A total of 168 rooms and been recovered in a record time. After the roof had been reinstated and the interior had been cleaned and re‐decorated, the students were able to move back in.

Summary – Fire Damage Restoration

London is a very cramped city and finding accommodation for 168 students at very short notice was both difficult and expensive. The longer the students were in temporary accommodation the greater the financial burden to the university and the insurance companies. A quick turn around of this fire damage cleaning services in London was essential.

Hydronic heater drying proved to the best solution. When compared to traditional drying equipment (dehumidifiers); 12 weeks (84 days) would be needed to dry each phase.

Hydronic heating saved 77 days per phase; the total project potentially saved 385 days or a year of disruption and financial problems.